Introducing Thermofusion

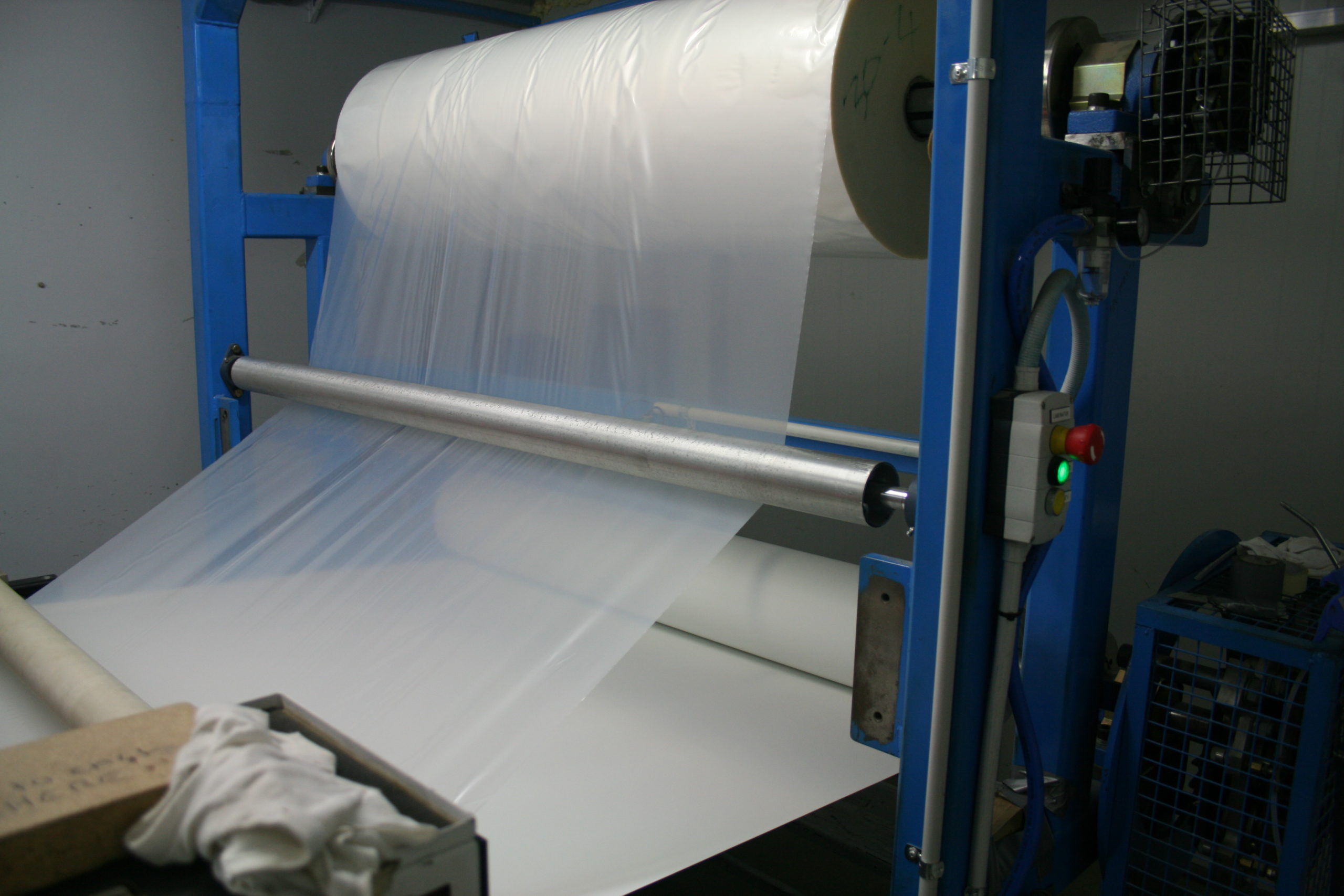

Modernforms’ doors & panels undergo a new-aged process; thermofusion. Taking a step above thermolamination, we attain a world-class gluing system exceeding all expectations of vinyl-wrap applications for over 18 years. This process process eliminates the chances of peeling and swelling, and ensures your products are of high quality, durable and hygienic for years to come.

With an extensive range of contours & colours, our thermofusion doors & panels allow for unmatched

Modernform Doors hold the first robotics system in Australia for CNC machining ensuring a quick turnaround.

Whether your renovating or building a new home, we’re able to transform your home.

This is our promise.

Modernform Doors is wholly owned and operated in Western Australia and at the forefront for company growth & development. Come visit us today and see why we’re the market leaders in cabinetry applications.